van Beest GmbH

van Beest GmbH

The Company van Beest GmbH

The Van Beest Group has been operating since 1922. Dirk van Beest was a blacksmith in the home of the Dutch dredging industry: Sliedrecht, close to the Port of Rotterdam. Since more than 90 years van Beest produces high quality shackles.

Thanks to the high level of expertise in forging work van Beest has secured a competitive advantage with ist shackles. This was a starting shot for a network of professional users which extends today worldwide.

The Trademark Green Pin®

In the 70’s the trademark Green Pin was introduced, whereby the product quality was underlined and recognition and demand was promoted worldwide. Green Pin® shackles are manufactured in the production facility in Sliedrecht, Netherlands. Therefore is is a real „Made in Netherlands“ product.

Van Beest shackles are made for different lifting application for different branch like, oil and gas, industry, mining, shipping and fishing.

Quality Standards of Van Beest

The quality standards and the construction of their products are the result of the desired requirements from their customers.

Van Beest products meets a large number of internationally recognized standards. The company is certificated by Lloyds ISO since 1993 and currently by ISO 9001-2015.

Van Beest has production sites in the Netherlands, Germany, France and the USA such as distribution centres in more of 90 countries around the world.

Surface Treatment of Green Pin shackles

All shackles of Green Pin are available with following surfaces:

- hot-dip galvanized

- galvanized

- painted

- raw

It always depends for which purpose the shackles are used for.

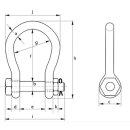

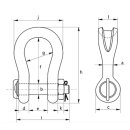

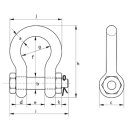

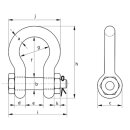

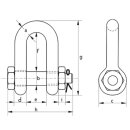

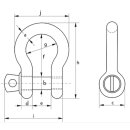

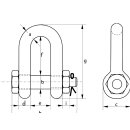

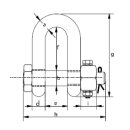

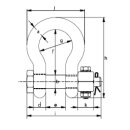

Fixed Nut Shackles

Shackles can also be used in permanent constructions. As a result, the shackles may be exposed to high loads and / or extreme vibrations. In these cases it can happen that the nut moves over the thread over time. To avoid this risk there ist he possibility to acquire Green Pin Shackles with fixed nuts.

The shackles are equipped with the fastening bolt AISI 316 which is drilled through the nut and the shackle bolt. The fastening bolt will turn with two pairs Nord-Lock washers and lock nut attached which holds the shackle nut in position. The Nord-Lock wedge lock washer clicks into place with extreme vibrations or dynamic loads.

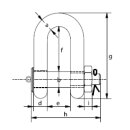

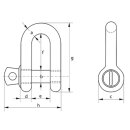

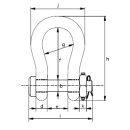

Installation of Green Pin Shackles

Correct assembly is very important for shackles. Always make sure that the shackle bolt is correctly screwed into the shackle eye. You also need to make sure that the shackle pin is the correct length so that the bolt can be screwed completely into the shackle eye. A twisted bolt, a too tight thread or a slightly offset shackle eye can cause the bolt to sit incorrectly. In this case the shackle must NOT be used.

Make sure the shackle is properly supporting the load that means along the axis of the shackle body centerline.

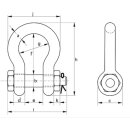

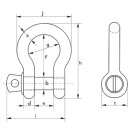

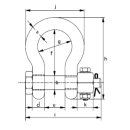

Avoidance of lateral loads

Side loads should always be avoided because the shackles were not designed for this purpose. If lateral loads cannot be avoided the WLL of the shackle must be reduced.

If you use shackles in conjunction with multiple strands you should pay attention to the angle between the strands. Because the angle increases, the load on each individual strand also increases and at the same time on every shackle.

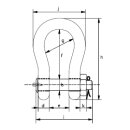

If you want to connect two strands with the hook of the lifting device a bow shackle is required. The hangers must be attached to the shackle body and the shackle bolts have to be positioned in the hook.

The angle between strands must not exceed 120 °. Is it a symmetrically suspended load the shackle can also be loaded with the maximum specified WLL. You can avoid extreme stress on the shackle by adding a spacer on both sides of the shackle pin.

Please note: Do not try to make the opening of the shackle smaller. No matter how, because that has a negative impact to the mechanical properties of the shackle.

If you use a shackle from a number of rope-blocks to secure the top block, the load on the shackle increases accordingly for the value of the resulting tensile load.

Avoid applications where the shackle pin could rotate because of movements. Use a shackle with a safety pin or with nut and split pin i fit should not be possible to avoid movement of the load.